TextiTherm® by ILO Technology

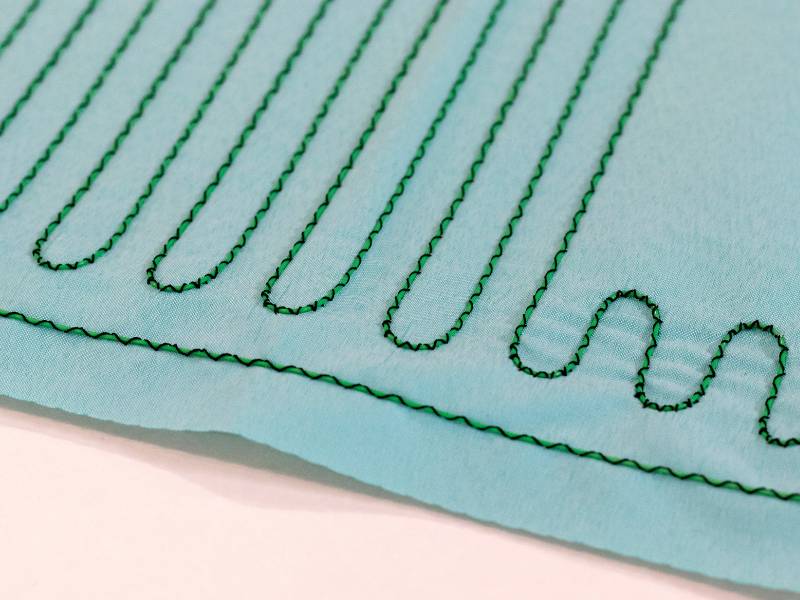

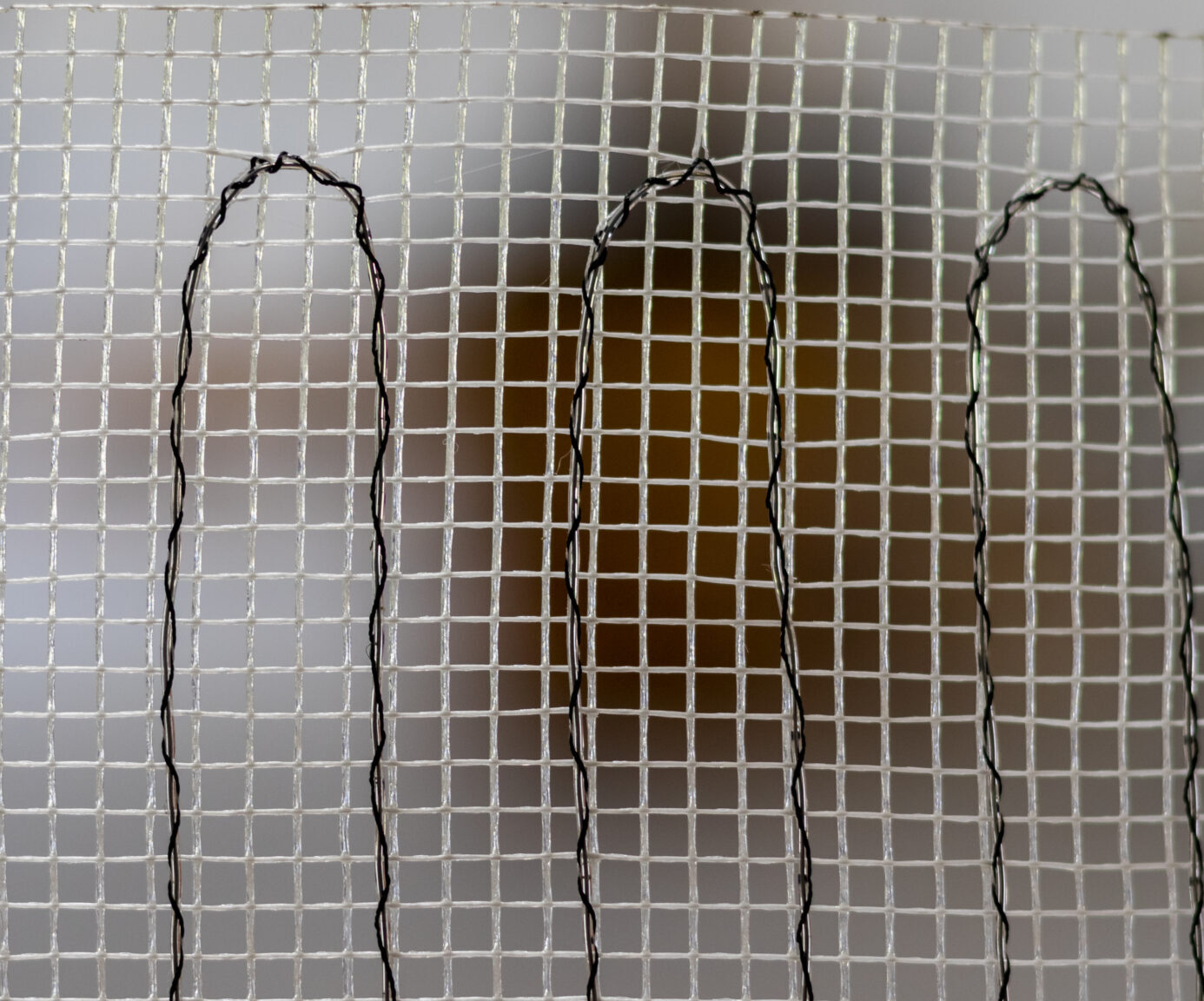

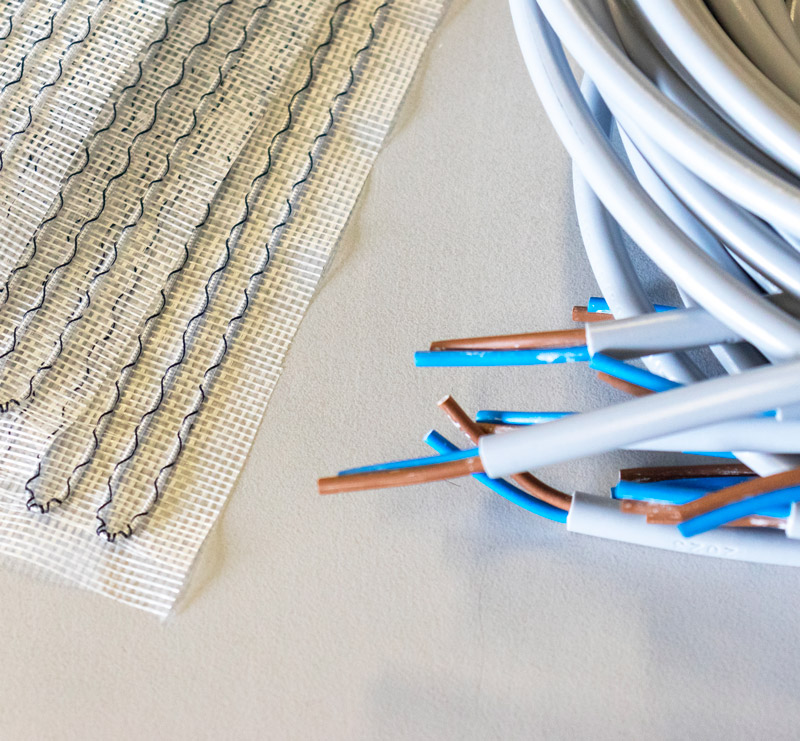

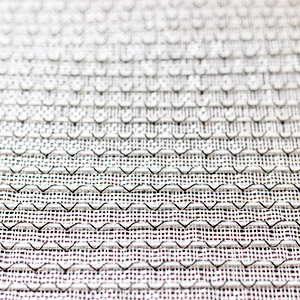

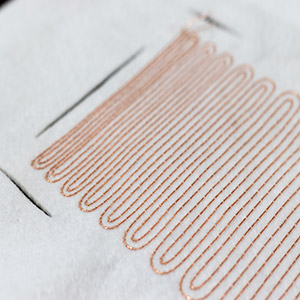

Welcome to ILO Technology, your specialist in the manufacture of advanced technical textiles. With our technical embroidery machines, we integrate heated conductive threads on a variety of textile substrates.

We work closely with you to design the ideal shape, size, material and layout for your industrial application, while aiming for simple, cost-effective production of your smart, functional textiles.